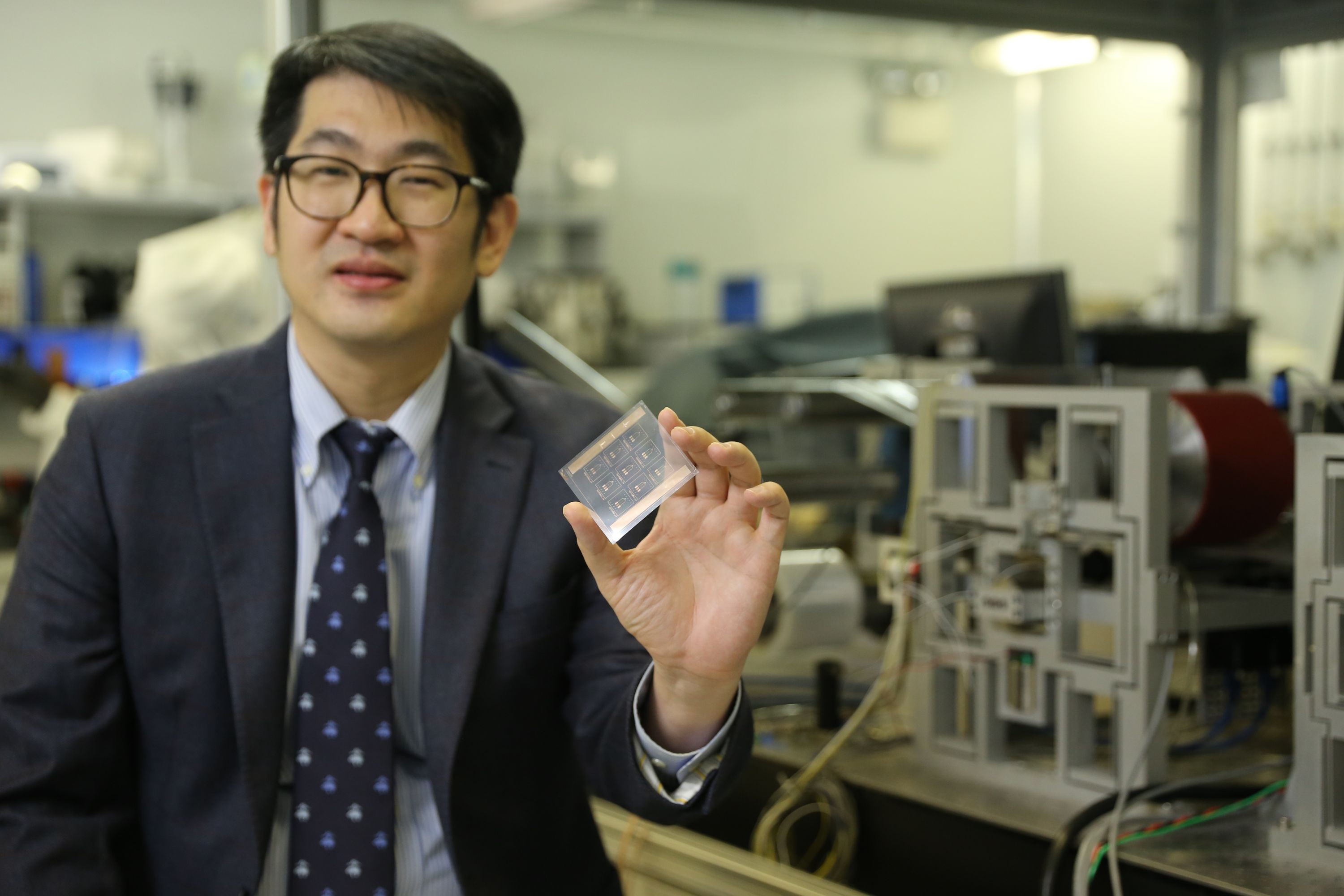

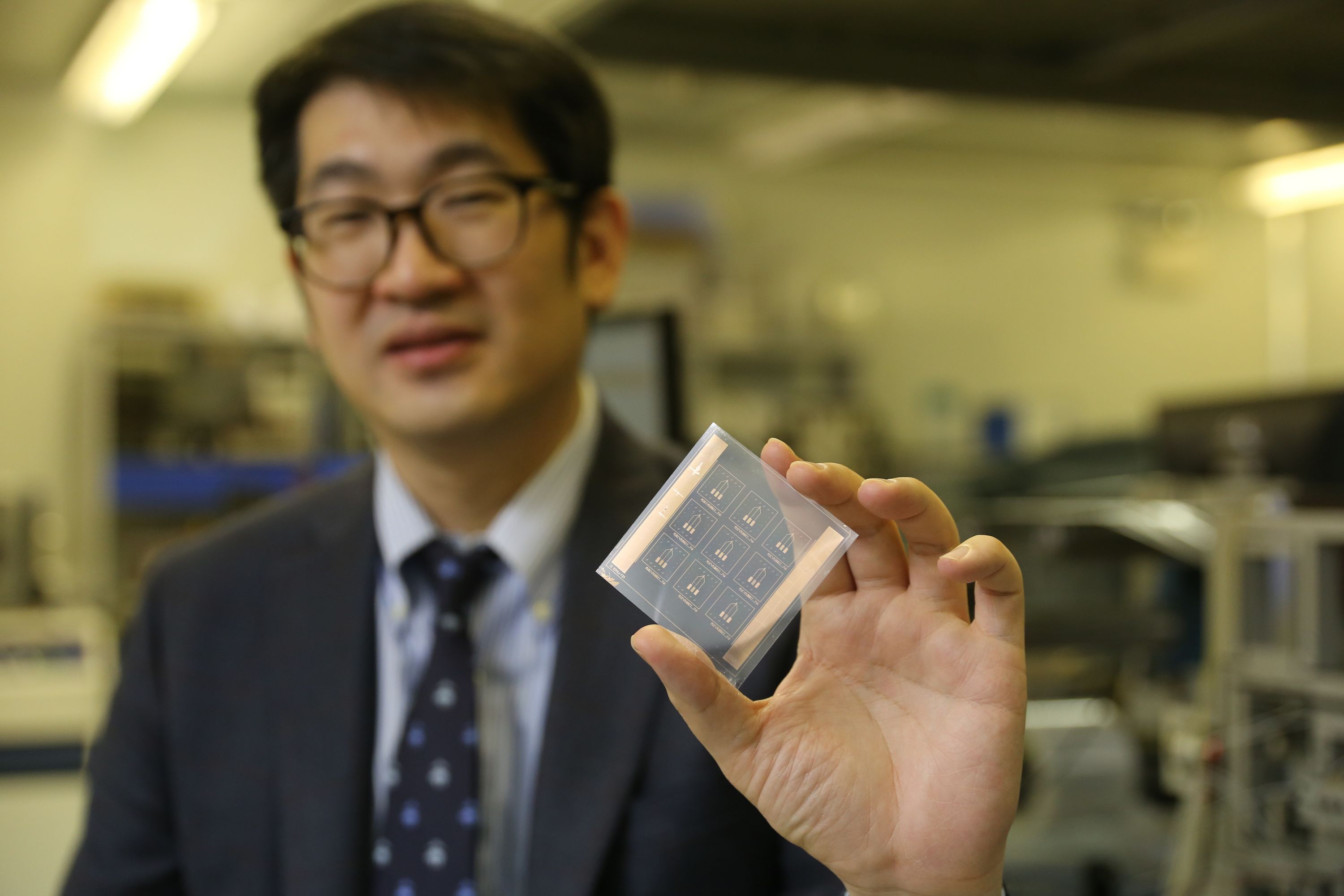

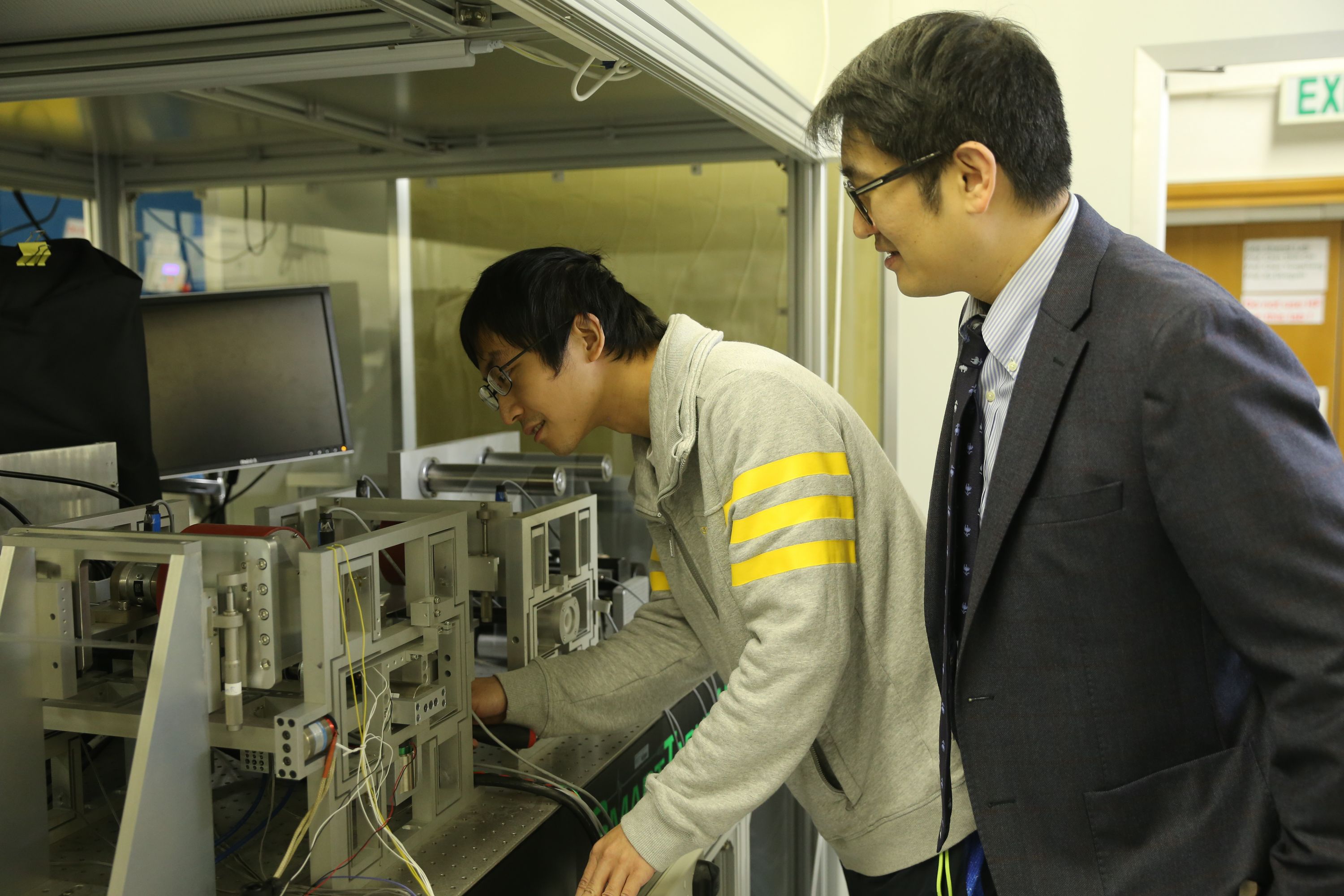

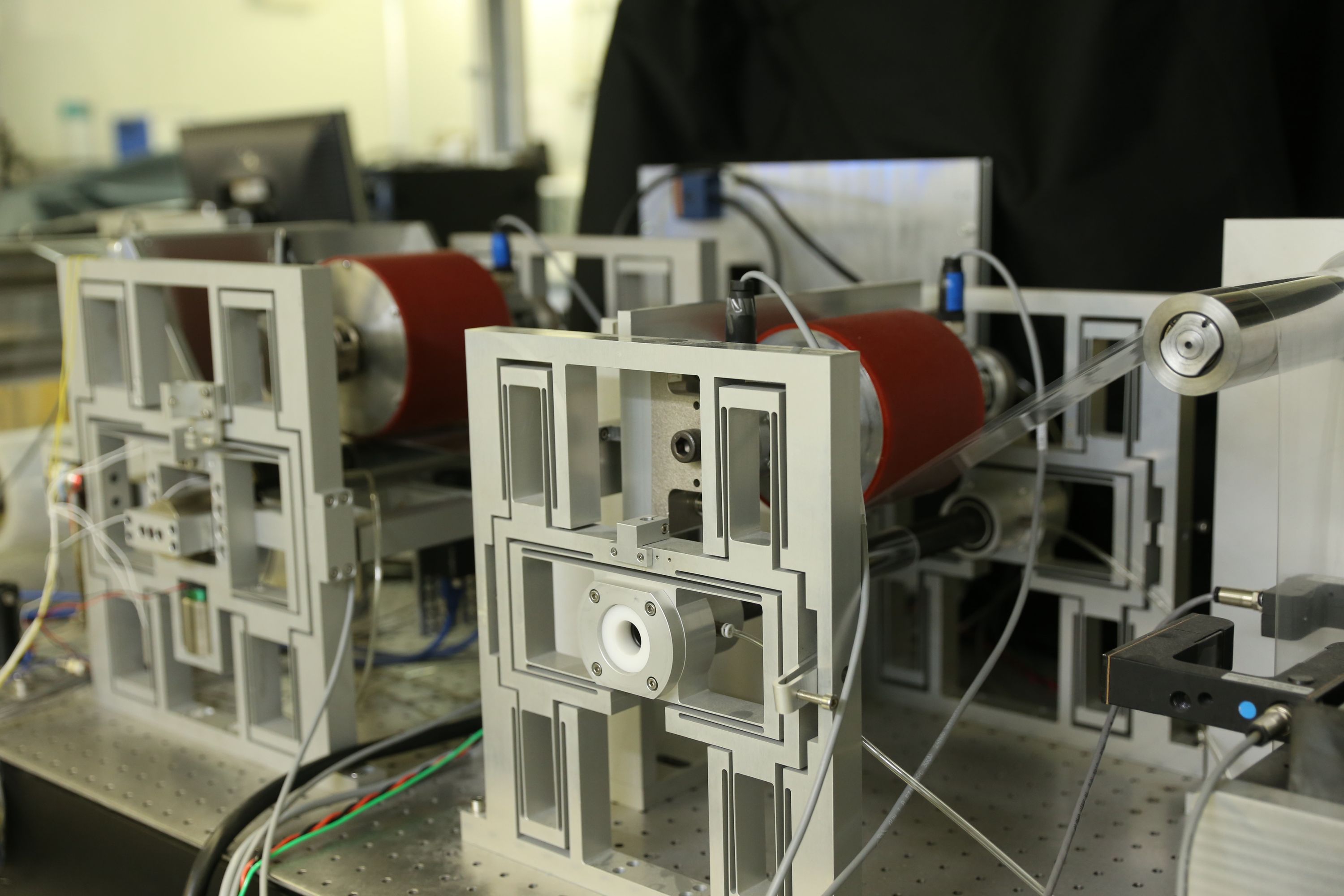

Professor Shih-Chi Chen and his team from the Department of Mechanical and Automation Engineering, the Faculty of Engineering, The Chinese University of Hong Kong (CUHK), have developed a flexure-based multilayer roll-to-roll (R2R) printing system that simultaneously achieves nanometer-level printing resolution and submicron-level overlay accuracy, enabling mass production of high resolution flexible electronics at low cost. The research result has been recently published in the journal Precision Engineering. R2R printing technologies have been widely used in many important fields, such as the fabrication of organic photovoltaics and touch screen electrodes, due to their tremendous advantages in throughput and cost as well as the capability to fabricate multilayer functional structures and devices on various flexible substrates, including ultra-thin glasses and polyethylene terephthalate (PET) films. A precision multilayer R2R printing system will help realize the fabrication of high performance flexible electronics. Flexure-based multi-axis nanopositioner realizes nanometer-level contact printing on flexible substrates. Optical gratings and transparent electrodes produced by optical and electron-beam lithography are essential components in a wide range of optoelectronics devices, such as touch screens, organic light emitting diodes (LED), and organic photovoltaic cells. However, these processes are complex, expensive, and need to be performed in a cleanroom, resulting in low productivity and high cost. On the other hand, although soft lithography-based techniques, such as microcontact printing (MCP), can overcome the diffraction limit to achieve nanometer resolution and operate in a non-cleanroom environment, large scale manufacturing has yet to be realized due to the challenging requirements in the ultraprecise printing force and system stability. To solve this problem, Professor Shih-Chi Chen and his team have recently developed and constructed a multilayer R2R printing system for fabrication of flexible electronic devices, where various contact printing methods can be applied to the system. The new R2R system is based on two flexure-based multi-axis positioners, which demonstrate nanometer-level repeatability and multi-axis error correction capability, and achieves 100s nm precision in combination with multiple-input and multiple-output closed-loop control algorithms. Experiments indicated that the system can control the roller position within 200 nm and reach a highest print resolution of 100 nm in a non-cleanroom environment. The R2R system can readily be scaled up for cost effective and high throughput fabrication of flexible electronics. New vision-based multi-axis alignment method achieves submicron overlay accuracy for the first time in R2R printing history State-of-the-art R2R systems can only print multilayer patterns with an accuracy of tens of microns, largely due to the use of traditional mechanical components and bearings with low repeatability and precision as well as conventional methods for monitoring the web position with unsatisfactory sensitivity. This prevents the manufacturing of high-resolution multi-layer electronic and photonic devices in micro-nano scale, such as organic thin-film field effect transistor (FET) and photonic metamaterials, e.g., terahertz perfect absorber. To address the issue, the research team introduced a vision-based alignment method and algorithm to the R2R printing system, where a pair of low cost cameras are employed to monitor the hybrid alignment marks; the acquired images are processed in real time by the pattern recognition and phase estimation algorithms to produce high resolution position feedback signals for controlling the two multi-axis roller positioners. Experimental results show that the system achieves better than 1 μm layer-to-layer registration accuracy – the first demonstration of submicron overlay accuracy on a R2R system. Based on this system, FETs were continuously fabricated on a 4-inch PET web to verify the precision, reproducibility and stability of the system. Professor Chen pointed out that the new R2R system has substantially extended the performance envelope of R2R printing technologies to realise emerging applications that require nanometer resolution and submicron overlay accuracy, e.g., flexible printed circuits and various optoelectronic devices. The system can readily be scaled up for industrial processes and generate impact to the manufacturing industry. |

|